Final Project Summary and Current State of Spiral Development

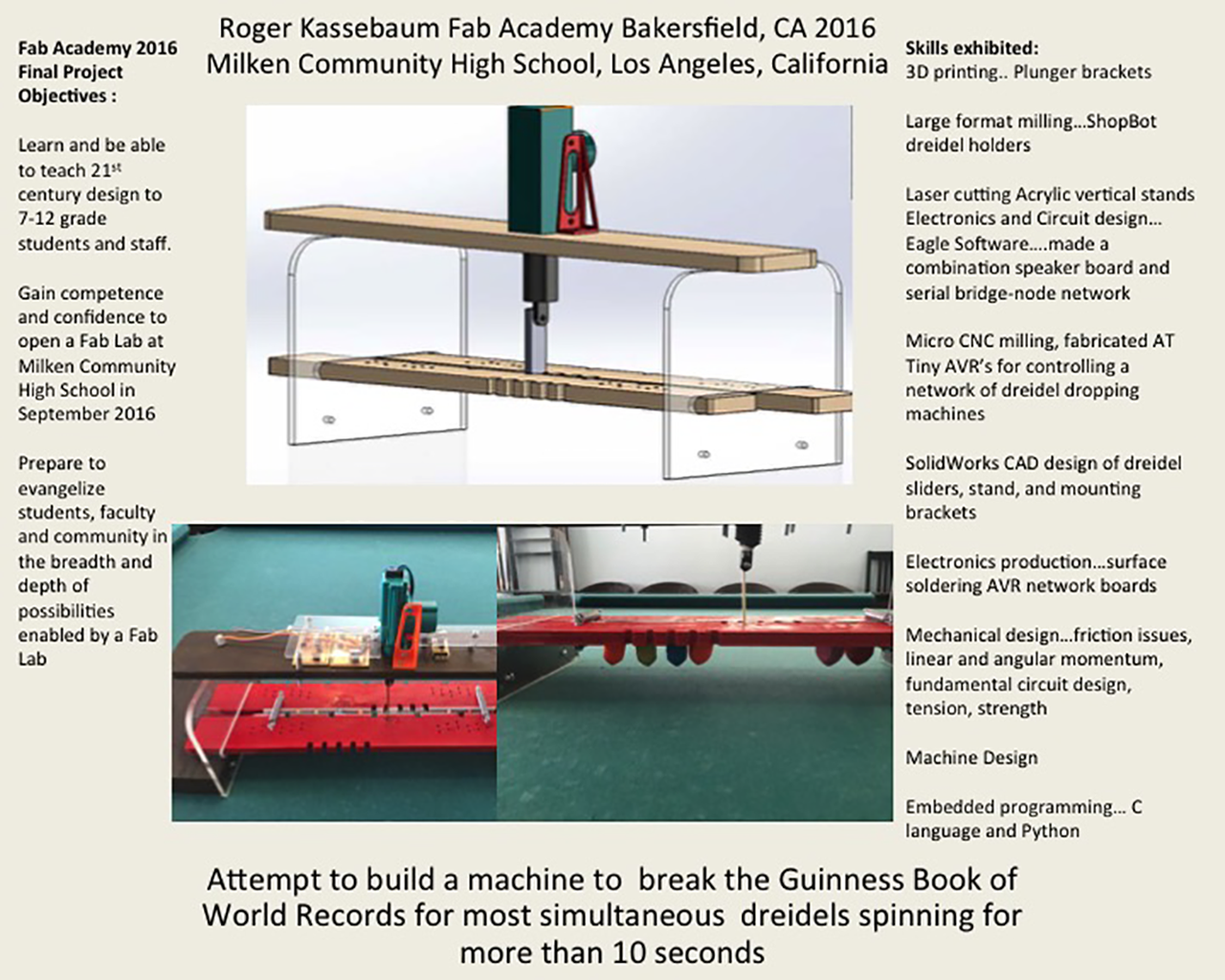

My final project was to make a node in a network of nodes where each node was a dreidel spinning machine/robot. The machine would would be loaded with an unspecified number of deidels and then spin them so that they spin for ten seconds. The ultimate goal would be to network enough nodes so that the total number of dreidels spinning for ten seconds would exceed the current Guiness Book of World Records. (approximately 1200)

I wanted to incorporate a large number of the assignments in this course into the final project. I succeeded in that attempt except I did not use composites, vinyl cutting or moulding/casting. It would be rather easy to make some signage with vinyl and I could have easily made a mould and cast some dreidels. I could have made the horizontal actuator support out of a composite, so going forward I might include these in a revised version so I can use it as a demonstration to explain to students, staff and administration all of the fabrication techniques in one model project.

I wanted my project to be something other than what I am known for. My current school identifies me as a "science" guy. My background is in physics, I have a math minor and I teach science research and robotics. I am starting a Fab Lab in my high school in September 2016, and I want to bring the maker philosophy into the entire school. I thought by doing some playful learning like making a dreidel spinning machine might help bridge the gap between discipines. The ability to make almost anything should not be religated to science and robotics. It is a challenge to change the mindset that making things is not relegated to what was once called shop class.

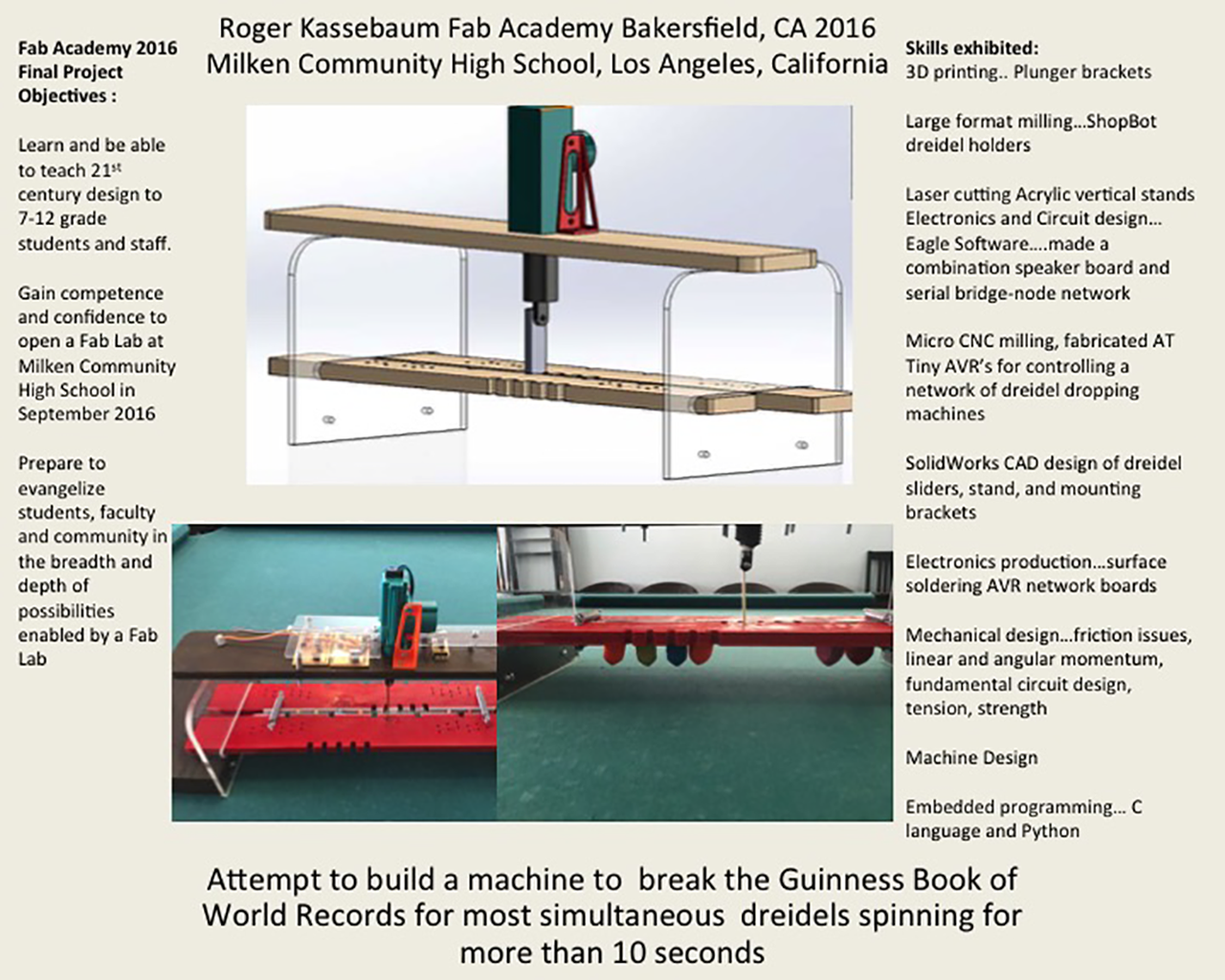

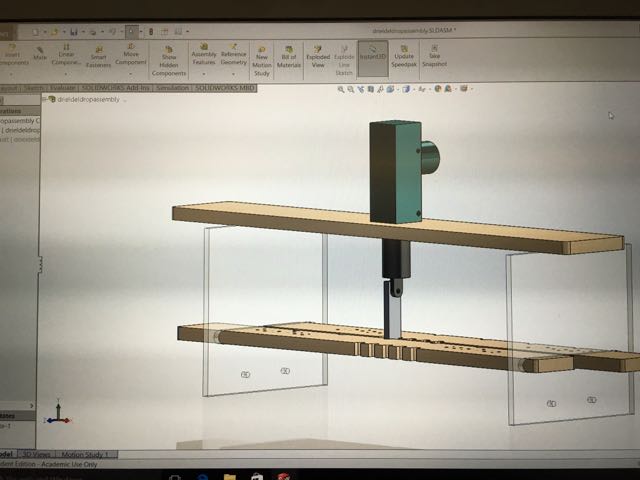

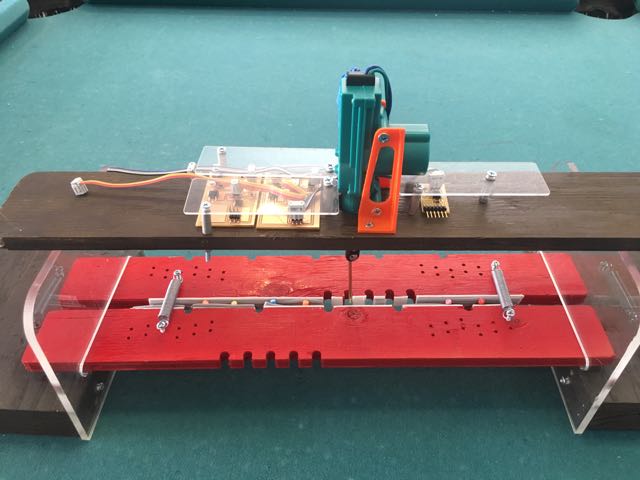

This is a Solidworks CAD assembly file of one of the nodes of a network that will spin and drop driedels that must spin for 10 seconds as required by The Guiness Book of World Records.

What will it do? The current design will spin a small number of driedels for the required 10 seconds by spinning the stems of the driedels by utilizing two spring loaded wooden rectangular pieces in opposing directions. The springs provide diagonal pressure to both grip and rotate the driedel stems when a 12V car door lock actuator pulls up a pin to release the two spring loaded boards.

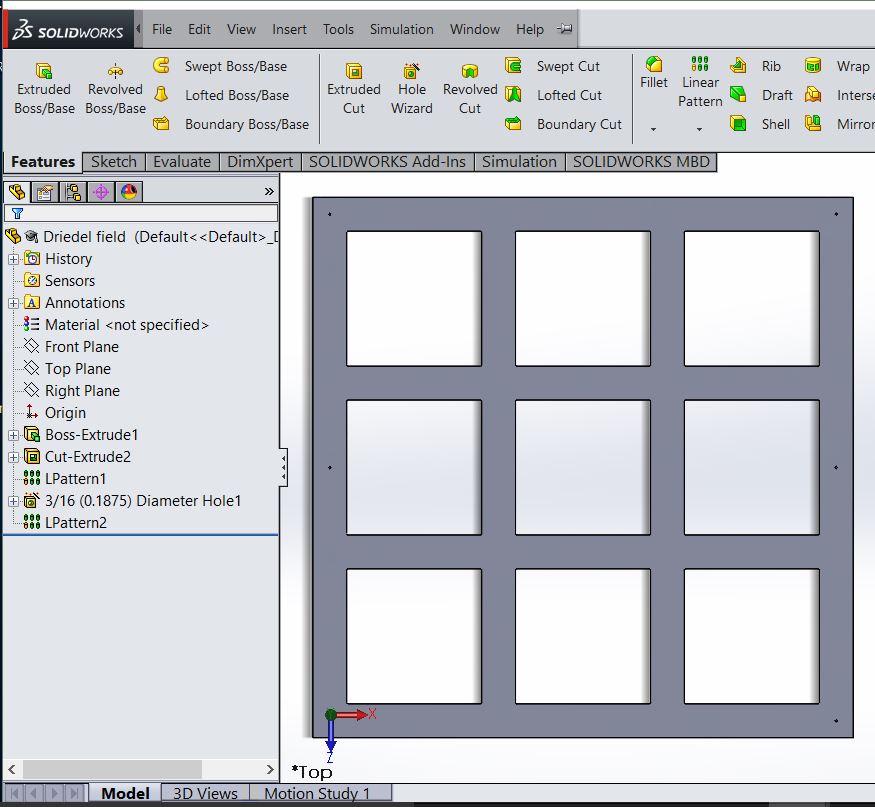

Solidworks design of a holder that will hold nine of the above devices. A node in a network of nodes will control droping devices shown above to drop driedels in each of the white squares. The holder is made of a 4 foot by 4 foot sheet of half inch plywood. In theory, one could make as many nodes as required to break the world record of 1200 simultanious driedels spinning for 10 seconds.

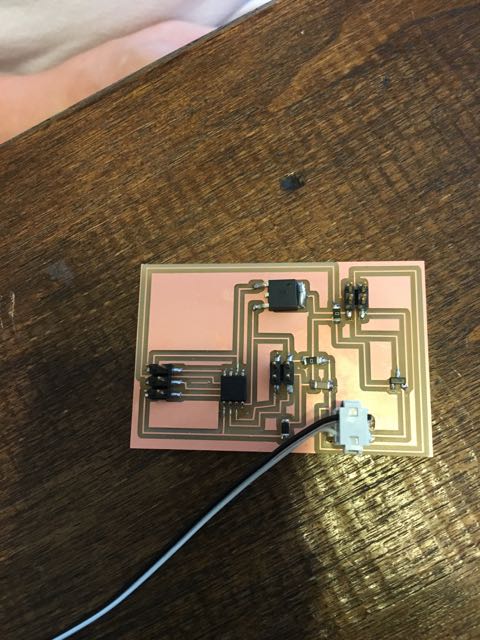

Both a Haas SR 100 router and the Shop Bot were used to make the horizontal red sliding boards and the brown horizontal board. The clear plastic bookends holder, the bridge and nodes are proteted by laser cut clear plastic. The green car door lock actuator is held in place with an orange 3D printed bracket designed in Inkscape. The bridge connecting a computer USB serial port to the node boards is a board I made from Neil's code in the networking lesson. The nodes are a combination of the nodes in the lesson and the sound board in the previous output lesson.

This is the modified combination of the node and sound board from previous lessons on networking and output (sound). Beyond the combination, the Mosfet is replaced with a larger current capacity and and external 12 V power input to drive the 12V door lock actuator.

Dreidel droping grid cut using our Haas SR 100 CNC router.

Following are links to weeks that I worked on the final project.

Week 2 Designed sliding dreidel holders.

Week 4 Made ISP programing board.

Week 7 Designed and made dreidel field holders.

Week 16 Programmed prototype dreidel dropping network boards.

Week 17 Designed, fabricated, programmed dreidel network boards.

The sequential development of the final project is available on the pages documenting each of the 18 weekly assignments. All the files are on in the File Repository page on the landing page of my web site.

What materials and components will be required?

Currently I am using cheap plywood to make most of the parts of the device, but I may go to HDPE for the final version. I am also using cheap springs, a network of PCB boards, the cheapest dreidels I can find online and a automobile power door lock from All Electronics. www.allelectronics.com

I Where will they come from? I picked up a sheet of 4x8 foot plywood from Home Depot $15.00, some springs and door lock motors from All Electronics and some cheap dreidels from Amazon.com.

How much will it cost?

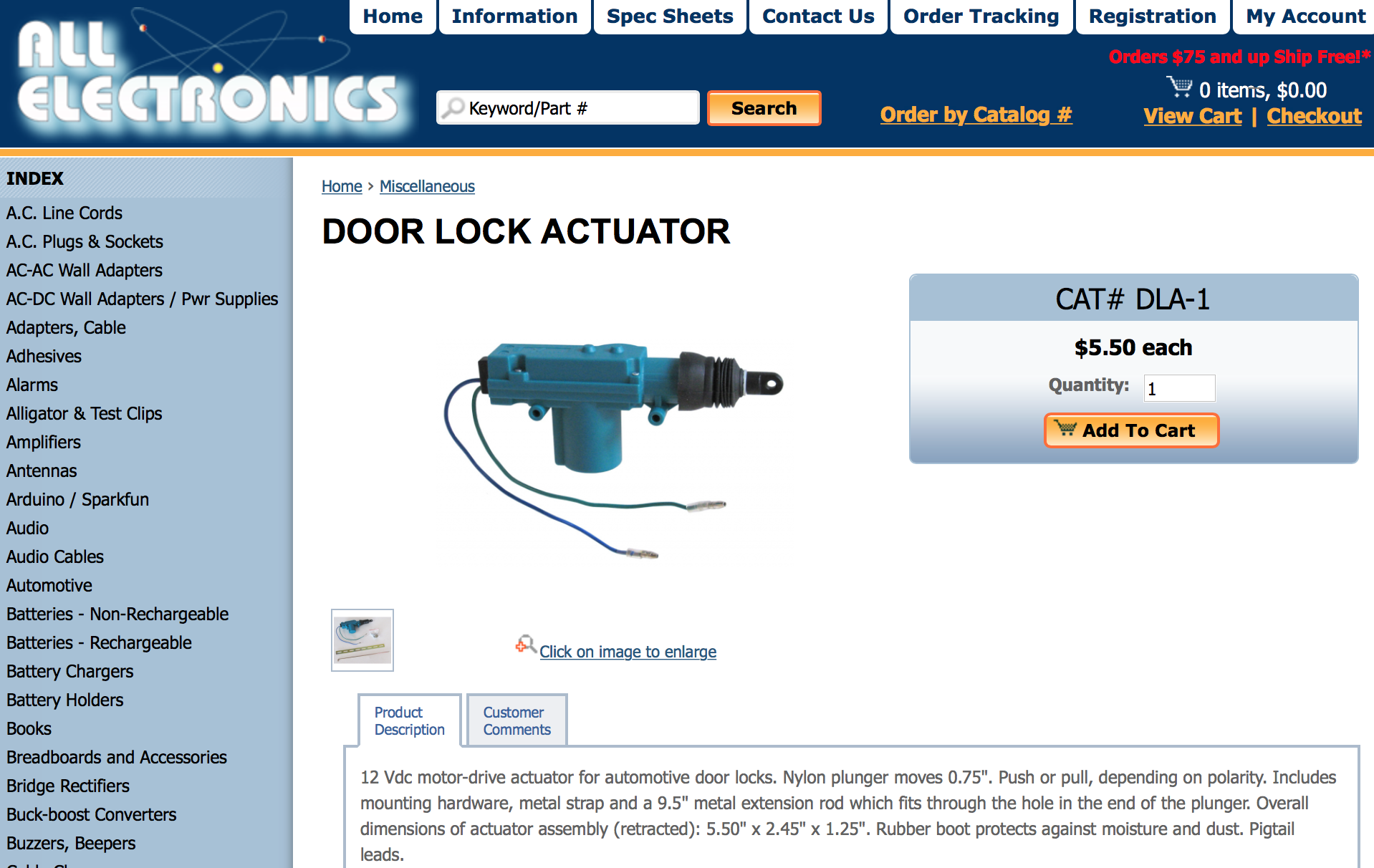

$15 to $20 for a sheet of plywood, I might need four sheets to break the world record. $5.50 per door lock actuator (I might need six to ten of them to actually break the world record. The springs were 35 cents each. Maybe $10.00 total. Fab Inventory parts for components might be $50 for enough to break the record. My goal is actually to build a master-slave network of only two or three slaves and continue the spiral prototyping design to drop about 20-50 dreidels. The next challenge will be to go into production and make enough modules to break the record at my school in December. I am thinking I will need a few hundred dollars to buy the 1200+ dreiedles and the above parts.

What parts and systems will be made?

Wooden or HDPE dreidel spinners, wooden dreidel field support, modified sound/network boards to actuate the door opener motors, support structure for dreidel dropping mechanism, electronic board enclosures. Everything will be made from the Fab Inventory except the car door actuators, the wood, the plastic dreidels, and the springs. The dreidels themselves could be made, but at 19 cents each, and I need over a thousand of them....I will purchase the dreidels. I do have future plans to mould and cast some dreidels to see if I can improve the performance and consistency.

I am rather certain that my dreidel spinning machine will have no commercial value and I am not concerned about anyone copying my design. I don't even need to be credited with the idea. I actually hope others find value in it and I hope they improve upon the design. I decided to go forward with a design that I knew would have no commercial value and want to distribute it freely. I see a lot of educational value in the project at my school and I think I will have some students that will want to challenge my machine and build a better one. If things go really well, I hope to distribute a revised version of the machine and potentially control all of the machines via the internet and break the world record....from several places around the world...simultaniously. If other schools, teachers, or students are interested, I will share my Fab Lab website with them. They can download the files, see the explanations and pictures and contact me if they need help.

If I were interested in a license, I would likely choose Creative Commons CC BY-NC-SA. Attribution-NonCommercial-ShareAlike This lets others tweak, remix, and build upon my work non-commercially as long as they credit me and license their new work under the identical terms.

Car door lock actuator from All Electronics.com

Springs from All Electronics.com

Half inch plywood from Home Depot

Dreidels ordered from Amazon (19 cents each)